Cold aisle containment is a data center cooling strategy used to optimize the efficiency of cooling systems in server rooms and data centers. It is designed to create a controlled environment that separates the cold air supply from the hot air exhaust in order to improve cooling efficiency and reduce energy consumption.

Cold aisle containment is a best practice in data center design and management, as it helps improve energy efficiency, equipment reliability, and overall cooling system effectiveness. By separating the hot and cold air streams and directing cooling resources more efficiently, organizations can achieve cost savings while ensuring the reliable operation of their IT equipment

Hot Aisle Containment

Hot aisle containment is a data center cooling technique used to optimize the efficiency of cooling systems and reduce energy consumption in data centers. In a data center, servers and other IT equipment generate heat, and it's crucial to maintain the appropriate temperature to ensure the reliable operation of these devices. Hot aisle containment is one of the methods employed to achieve this goal.

Hot aisle containment is a data center cooling technique used to optimize the efficiency of cooling systems and reduce energy consumption in data centers. In a data center, servers and other IT equipment generate heat, and it's crucial to maintain the appropriate temperature to ensure the reliable operation of these devices. Hot aisle containment is one of the methods employed to achieve this goal.

The Need for Aisle Containment

- Energy Efficiency: Data centers are power-hungry facilities that require a significant amount of energy to operate, with a substantial portion of that energy used for cooling. Cold aisle containment reduces the amount of energy needed for cooling by ensuring that the cool air supplied to servers is contained within the cold aisle and not wasted in other parts of the data center. This results in lower energy consumption and cost savings.

- Equipment Reliability: IT equipment, including servers and networking gear, has specific temperature and humidity requirements for optimal performance and longevity. Maintaining a consistent and cooler temperature within the cold aisle helps ensure that the equipment operates within these recommended parameters, reducing the risk of overheating and equipment failures.

- Heat Management: Servers generate heat as they operate, and this heat needs to be efficiently removed to prevent equipment overheating. Cold aisle containment helps manage and control this heat by channeling it away from the IT equipment and into the hot aisle, where it can be more effectively extracted by cooling systems.

- Hot/Cold Air Separation: Without containment, hot and cold air can mix within the data center, leading to inefficient cooling. This mixing, known as air recirculation, can cause hot spots and temperature variations, making it challenging to maintain consistent cooling throughout the data center. Cold aisle containment ensures a clear separation between the hot and cold air streams, preventing recirculation and temperature fluctuations.

- Scalability: As data centers grow and evolve, it becomes increasingly important to have a scalable cooling solution. Cold aisle containment can be implemented in both new and existing data centers, making it a flexible and adaptable solution that can accommodate changing IT loads and configurations.

- Environmental Impact: Energy efficiency is not only about cost savings but also about reducing the environmental impact of data center operations. By minimizing energy consumption for cooling, cold aisle containment contributes to sustainability efforts by reducing greenhouse gas emissions associated with data center operations.

- Regulatory Compliance: Some regions and industries have specific regulations and guidelines related to energy efficiency and environmental responsibility. Cold aisle containment can help data centers meet these compliance requirements, avoiding potential fines or penalties.

- Operational Cost Savings: Beyond energy savings, cold aisle containment can lead to operational cost savings by extending the lifespan of IT equipment (reducing replacement and maintenance costs) and reducing the need for costly infrastructure upgrades to accommodate growing IT loads

In summary, the need for aisle containment in data centers is driven by a combination of factors, including energy efficiency, equipment reliability, heat management, scalability, environmental considerations, regulatory compliance, and operational cost savings. It is a practical and cost-effective solution for improving the overall performance and sustainability of data center operations.

Our Aisle Containment Solutions

Hot Aisle Containment (HAC)

In a hot aisle containment setup, the hot air expelled from IT equipment is enclosed within a containment system, such as plastic curtains, doors, or panels, to prevent it from mixing with the cold air in the data center. This design reduces cooling requirements and promotes better temperature control.

Cold Aisle Containment (CAC)

In a cold aisle containment setup, the cold supply air is enclosed within a containment system, while the hot air from the equipment is allowed to mix freely within the data center space.

Raised Floor Airflow Management

Data centers utilize a raised floor system to manage airflow. Adjustable floor tiles and baffles can be used to direct cold air where it's needed most, ensuring efficient cooling.

Containment Curtains and Panels

Flexible containment solutions, such as PVC strip curtains or panels, which are fire retardant can be used to enclose aisles. They are cost-effective and easy to install but may not provide the same level of containment as rigid systems.

Metal Fuse Link

Metal fuse links are commonly used in fire protection systems. When the ambient temperature rises due to a fire, the metal fuse link melts, allowing the fire retardant PVC Strip Curtains used in Containment area in Data Center to drop down thus facilitating the fire extinguishing system to access the area covered for containment.

Modular Containment Solutions

Some companies offer modular containment solutions that can be customized to fit a data center's specific layout and requirements. These modular systems are often easier to install and reconfigure as needed.

Rack-Based Containment

With this approach, individual server racks are equipped with doors, panels, or other containment features to isolate the airflow within the racks. Rack-based containment is highly flexible and can be implemented incrementally.

Containment Doors

Containment doors can be installed at the ends of cold aisles or server rows to prevent the mixing of hot and cold air. They are often used in conjunction with other containment solutions.

Benefits of choosing Us

- Cost Savings: Our containment systems can translate into cost savings for data center operators. Reduced energy consumption and improved cooling efficiency can lead to substantial operational cost reductions over time.

- Customization: Ability to provide tailored containment solutions that match the specific needs and layout of each client's data center. Customized solutions can maximize effectiveness and efficiency.

- Quick Installation: Our containment systems are designed for easy and fast installation.

- Scalability: Showcase how your containment solutions are scalable and can adapt to changes in data center configurations or equipment density. Scalability ensures that your products can grow with the client's needs.

- Regulatory Compliance: Our containment solutions help data centers meet environmental or regulatory standards. Compliance with regulations can be a critical factor for some clients.

- Competitive Pricing: Since we have our own products like PVC strip curtains and authorized dealers for GEZE, we will assure you the best price.

- Environmental Responsibility: In today's environmentally conscious world, our containment solutions contribute to sustainability and reduced greenhouse gas emissions.

- Data Center Safety: Our containment systems consists of fire-resistant materials and ease of access for maintenance and emergency situations.

- Return on Investment (ROI): Deploying CACS in an existing raised floor, room-oriented perimeter cooling layout is easier and less costly. However, HACS provides significantly more energy savings over CACS while maintaining a comfortable data center work environment temperature for perimeter IT equipment and workers. Retrofitting an existing perimeter-cooled, raised floor data center with HACS instead of CACS can save 40% in the annual cooling system energy cost corresponding to 13% reduction in the annualized PUE.(Reference:- White Paper 135)

Case Studies

Sample Proposed drawings given

by our team after assessing the site @ EPV Lab

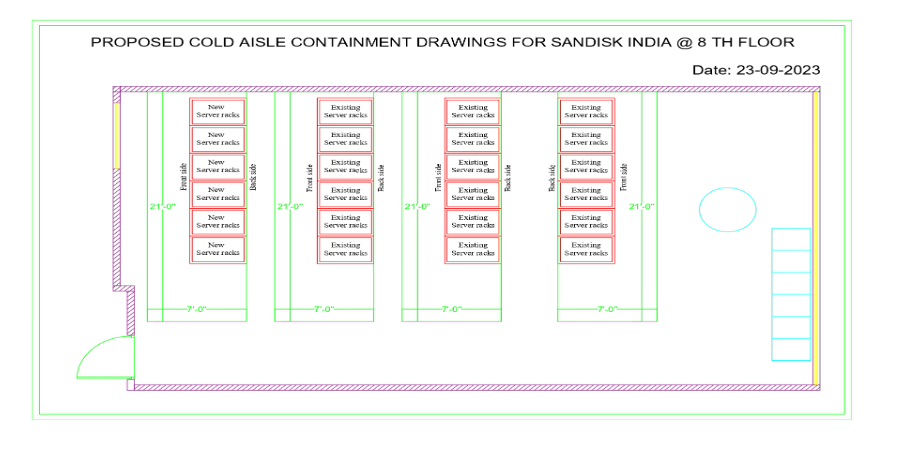

Sample Proposed drawings given by our team

after assessing the site @ SANDISK INDIA

Soft Cold aisle containment @SANDISK INDIA

4mm thickness Lexan Polycarbonate Sheet roof at Juniper Networks

Hard hot aisle containment at Juniper Networks

Cold Aisle Containment @ Dell Lab

Video of CAC using our automatic sliding doors

Aisle Containment Project @ Foxconn DataCenter, Bengaluru

Material Used

- Fusible Link

- SS Fixture

- Aluminium Channel with Cover

- Fire Retardant PVC Strip Curtain

- Polycarbonate Sheet

Lexan Polycarbonate Technical Data Sheet

| Typical Properties of Polycarbonate |

| Astm or UL test |

Property |

Unfilled |

30% Glass |

| PHYSICAL |

| D792 |

Density(lb/in3)

(g/cm3) |

0.043

1.2 |

0.052

1.43 |

| D570 |

Water Absorption, 24 hrs(%) |

0.12 |

0.12 |

| MECHANICAL |

| D638 |

Tensile Strength (psi) |

9,500 |

19,000 |

| D638 |

Tensile Modulus (psi) |

320,000 |

- |

| D638 |

Tensile Elongation at Break (%) |

60 |

10 |

| D790 |

Flexural Strength (psi) |

15,000 |

23,000 |

| D790 |

Flexural Modulus (psi) |

375,000 |

1,100,000 |

| D695 |

Compressive Strength (psi) |

12,000 |

18,000 |

| D695 |

Compressive Modulus (psi) |

240,000 |

500,000 |

| D785 |

Hardness, Rockwell |

M70 / R118 |

M92 |

| 256 |

IZOD Notched Impact (ft-lb/in) |

13 |

2 |

| THERMAL |

| D696 |

Coefficient of Linear Thermal Expansion

(x 10-5in./in./oF) |

3.9 |

1.2 |

| D648 |

Heat Deflection Temp (oF / oC)

at 264 psi |

270 / 132 |

295 / 146 |

| D3418 |

Glass Transition Temp (oF / oC) |

293 / 145 |

300 / 149 |

| - |

Max Operating Temp (oF / oC) |

250 / 121 |

270 / 132 |

| C177 |

Thermal Conductivity

(BTU-in/ft2-hr-oF)

(x 10-4cal/cm-sec-oC) |

1.3

6.9 |

1.3/6.9 |

| UL94 |

Flammability Rating

@ less than .45" (11.5mm) thickness

@ .45" (11.5mm) thickness and above |

H-B |

H-B |

| ELECTRICAL |

| D149 |

Dielectric Strength (V/mil) short time, 1/8" thick |

390 |

470 |

| D150 |

Dielectric Constant at 60 Hz |

3.17 |

3.35 |

| D150 |

Dissipation Factor at 60 Hz |

0.0009 |

0.0011 |

| D257 |

Volume Resistivity (ohm-cm)at 50% RH |

1016 |

1016 |

Benefits and solutions of choosing our Doors

Switch Door Solutions

- Door Closers.

- Floor Springs.

- Automatic Door Drives.

- Door Control.

- Hold Open Systems.

- Fresh Air Systems.

- Integrated Automatic Door Drives.

Sliding Door Solutions

- Single Sliding Door.

- Double Sliding Doors.

- Automatic Open by using motion

- sensor, wave motion sensor, touch sensor…

- Manual Sliding Doors.

- Customized Doors to fit the area.

Building Automation

Building automation makes your building a more comfortable place to be: safer and more comfortable, and you save more energy. It facilitates the monitoring and operation of all building technology, something that is indispensable in larger buildings. For efficient building management in a smart building, we can provide you with a unique networking offer. With our building automation system, we are pioneers in the networking of doors and windows. It is based on open communication standards and can be integrated into the building management system.

Conclusion

In summary, aisle containment is a strategy used in data centers to improve energy efficiency, cooling effectiveness, and equipment lifespan by directing cold air where it's needed and minimizing mixing with hot air. It involves physical barriers, components like grommets and ceiling panels, and best practices for design and maintenance. While it requires an initial investment, the long-term benefits in energy savings and equipment preservation make it a valuable approach for data center cooling.

Air-aisle-containment - Frequently Asked Questions

? What is Cosyst Devices?

Cosyst Devices is a leader in Data Center Air Flow containment solutions. Utilizing the best in cutting edge industry standard airflow containment technology we provide the solutions you need.

As demands within the Data Center industry have evolved, the need to effectively manage costs and efficiencies have increased drastically. An inefficient Data Center wastes money.

Cosyst Devices provides the cost effective and efficient Data Center airflow solutions you need. Our products will save you money, provide a short return on investment, and help extend the life of your IT equipment.

In short, Cosyst Devices will increase your Data Center cooling efficiency and profitability.

? What is Data Center Containment?

Containment is isolating and channeling airflow in hot and cold aisles utilizing doors and panels at the end of, between, and on top of cabinet rows. Containment is the most effective method of redirecting air flow.

A typical data center provides 60% more cooling than necessary to adequately cool the servers and eliminate hot spots, resulting in high energy costs. Airflow Containment prevents the mixing of hot and cold air and directs the conditioned air to the servers and the hot air back to the crack unit. Airflow Containment provides several key benefits, and depending on the customers’ needs these purposes will be weighted differently

? What are your products made of and how does this meet or exceed fire code requirements in data centers?

Our data center products are meticulously designed to meet and often exceed fire code requirements. Our Flexi clear PVC strip curtains are fire retardant, Polycarbonate sheets are fire resistant and we do provide smoke detectors if needed.

? How much is a standard installation?

? What is Airflow Containment?

Airflow Containment makes your data center more efficient by channeling your cold air to where it is needed and thereby reducing wasted energy. Airflow Containment also prolongs the life of your equipment by maintaining safe operating temperatures.

? Why should I get containment in my data center?

Containment is the most effective way to keep hot air and conditioned air separated. In a data center without containment, the hot air naturally rises towards the ceiling, creating air currents that mix hot and cold air compromising the efficiency of the cooling system. By isolating the hot and cold air through the use of containment, hot air is directed back to the cooling system and cool air to the servers. This enables higher set points units, eliminates hot spots, lower fan speeds, and can often eliminate the need for one or more CRAC units in larger data centers. In most cases, containment pays for itself in under three years.

? Is my data center efficient?

Chances are you’re wasting money!

Our specialized engineers can analyze and tell you if your data center is efficient and show you how to maximize your efficiency.

Up to 50% of a data center’s energy bill can be tied directly to providing cooling for IT equipment. It requires a great deal of resources to ensure your IT equipment is operating within suggested parameters.

It is estimated that 60% of the cool air supplied by CRAC air conditioning units never reaches the intended IT equipment through leaks or bypasses. In the past this problem has been addressed by over-cooling the entire IT environment and has resulted in wasted energy, unnecessary costs and lost data center capacity.

? Which is better, Hot Aisle or Cold Aisle Containment?

Hot aisle containment isolates the return air and directs it back to the cooling unit. The rest of the data center essentially functions as a 'cold aisle'. The primary advantage to Hot aisle containment is the warmest air is returned to the cooling unit, maximizing efficiency. The disadvantage is by isolating the hot air, there is a larger area to be cooled, slightly increasing cooling temperature requirements. Cold aisle containment traps and creates a pool of conditioned air by capping the top and ends of the aisle. The rest of the data center functions as a hot aisle. The primary advantage to cold aisle containment is the cool air is directed to the servers, minimizing the risk for hot-spots and reducing the space to be cooled. A disadvantage is a warmer working environment, and less efficiency in recycling air. Which option is best depends on several factors including size of the data center, obstructions, cooling hardware and design, etc..

? What do I need to design and quote a containment solution?

Cosyst Devices creates custom containment specific to each job. We provide a simple Quote Guide and work sheet to help make sure the right information is gathered to provide your customer with the best solutions. For more complex jobs with uneven cabinet heights, obstructions such as pillars and ladder racks, and open spaces between cabinets, send us a layout of the data center, and we will help you design the solution. Our sales people have all been in data centers and helped with installation and understand how to build robust containment solutions.